We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Blog - How to calculate the spring rate of a tension spring

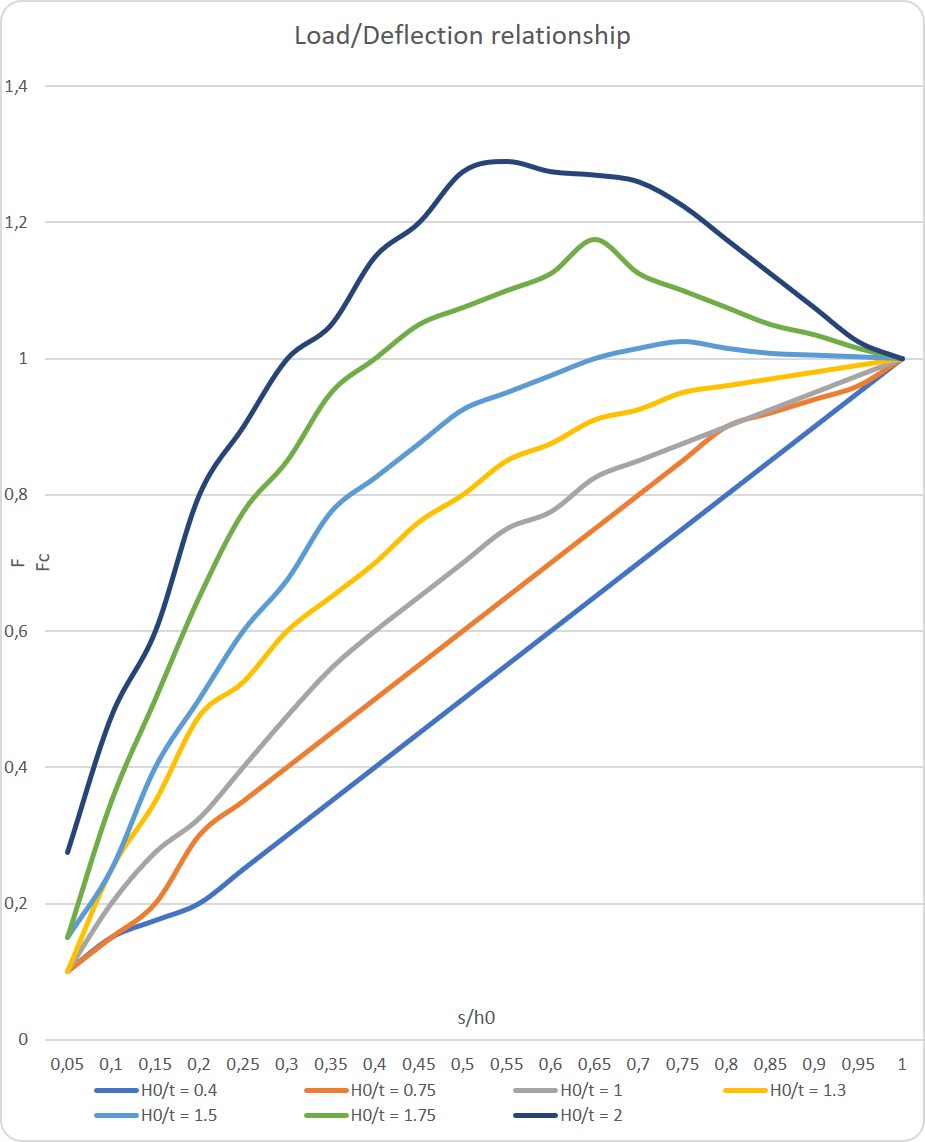

In this piece explains how you can calculate a spring constant of tension springs and use the spring constant to make a design of a tension spring. This piece is a deepening on the standard calculation of spring constant. Parallel to this piece is spring constant of compression springs and spring constant of torsion springs.

General information:

The function of a tension spring is to withstand a certain straight stretching force on the spring. The tension springs, unlike compression springs, have no space between the turns. The coils of tension springs are wound in such a way that the coils want to creep onto each other, this is only impossible due to the design. Each turn provides power on the previous turn. This ensures that the tension spring always provides the force to return to its original position. However, this wrapping method has an additional effect. Due to the tight wrapping method, there is preload on the tension spring. The preload (F0) is a minimum of force that is required to get the tension spring in motion.

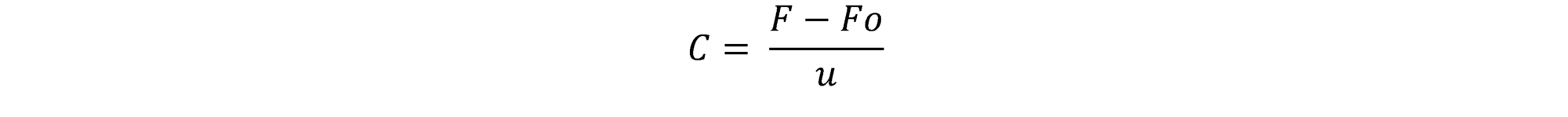

The basic calculation to calculate a spring constant is C = F/u, see the standard calculation of a spring constant. In this piece we go into more details in terms of; influence of preloads, tension spring design and the calculation of the spring constant in this way.

This piece states:

- What influence does the preload have on the strength of tension springs?

- How do I apply the formula to calculate a spring constant of tension springs?

- How do I arrive at a design of tension springs based on the spring constant?

How does preload affect the spring rate?

Preload is a parameter unique to tension springs. The preload can be used to keep objects from moving unless the force is greater than the bias. Preload works as follows:

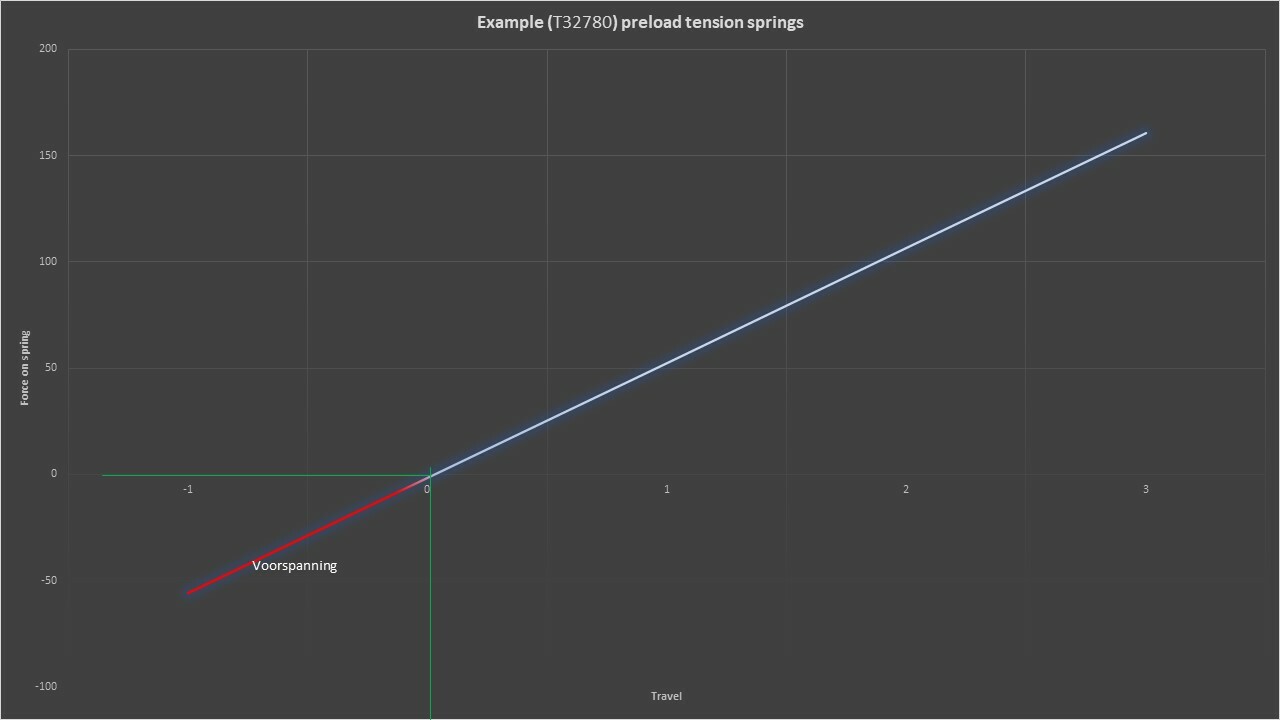

Preload in the graph occurs between position -1 and -0.

This tension spring only stretches from point 0. It takes 55.66 Newtons to reach point 0. From 55.66 Newtons, the spring rate of the spring starts to work.

Preload is important if you want the tension spring to stretch a certain length with a certain force. If we want this spring with a spring rate of 54.12 Newtons to stretch 3mm, it is necessary that the total force for extension is:

55.66 (preload) + 3 (mm)* 54.12 (spring constant) = 218.02 Newtons. Additionally, you can use the preload when you do not want movement of your object below a certain force.

Formula spring constant tension springs

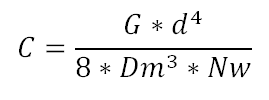

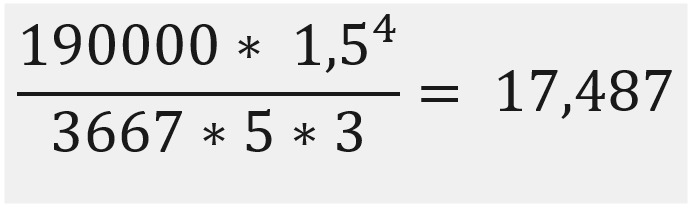

The spring constant of tension springs is expressed in Newtons per mm (N/mm) of extension. This depends on a number of parameters in the calculation. First of all, the Slip Modulus in Mpa is needed (G). This depends on the material used, request this parameter from the spring specialist. Furthermore, the wire thickness (d), the diameter of the spring center to center (Dm) in millimeters (mm) and the number of active turns (Nw) are required.

C = Spring constant in N/mm

G = Slip Modulus (Mpa)

d = Wire thickness (mm)

Dm = Diameter spring center to center (mm)

Nw = Number of working windings

Use the following table to play with the tension spring rate.

|

Parameter |

Bigger |

Smaller |

|

d |

Stronger |

Weaker |

|

Dm |

Weaker |

Stronger |

|

Nw |

Weaker |

Stronger |

To further see how this works theoretically, two examples have been worked out, these are the same examples as with the compression springs and torsion springs.

- Example one: Your object is 85 kilograms (850N) and you want the tension spring to stretch 5cm (50mm).

Example two: Your object is 65 kilograms (650N) and you want the tension spring to stretch 5cm (50mm).

We first need to calculate the effect on preload on the spring constant.

Influence of preload on the spring rate of tension springs

Preload is only calculated when an tension spring begins at the rest position. For the total required force, the spring begins in a rest position. The standard formula for the spring constant measures point A and point B in extension without rest position. To calculate the total force of the tension spring or a specific extension in mm, the preload must be included in the calculation. We therefore adapt the standard formula to calculate spring constant between point a and point b:

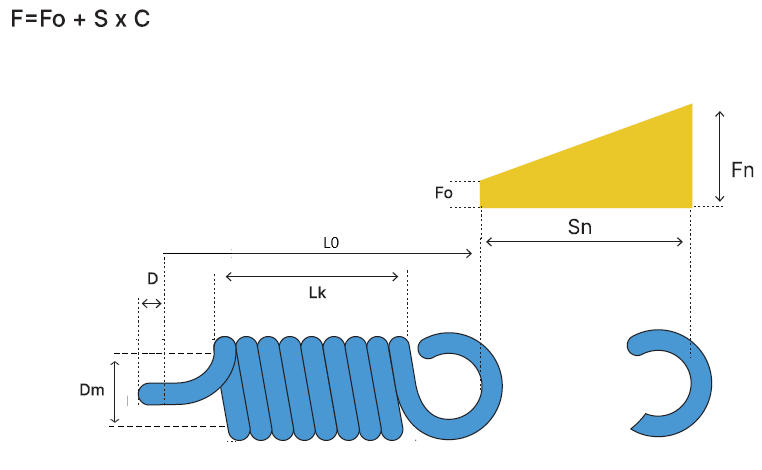

F = Total required force expected from the spring.

F0 = Force preload in the spring.

u = Total extension of the spring that we want.

The preload has been subtracted from the total force. Because the preload of force is in the spring, this does not have to supply the spring again when stretched. As an example:

|

Influence preload |

A |

B |

C |

|

Required force |

850 |

850 |

850 |

|

Preload |

50 |

75 |

100 |

|

Spring travel required |

50 |

50 |

50 |

|

N/mm |

16 |

15,5 |

15 |

In the our two examples, we take into account the following basic parameters:

- Standard German eyes

- Preload of 50 Newtons.

With those value’s we are searching for tension springs with:

- Example one: Your object is 85 kilograms (850N) and you want the tension spring to stretch 5cm (50mm). Then we need a spring constant of: C = 16 (850 – 50) / 50

- Example two: Your object is 65 kilograms (650N) and you want the tension spring to stretch 5cm (50mm). Then you need a spring constant of: C = 12 (650 – 50) / 50

With the previous two examples we can fill in the formula to arrive at a design. The result of the formula is given. Now the question is, which d, Dm and Nw belong to this?

|

Parameter |

Meaning |

Value |

Example 1 |

Example 2 |

|

C |

Spring rate |

Newton per mm |

16 N/mm |

12 N/mm |

|

G |

Slip Modulus in Mpa |

Megapascal (Mpa) (a unit of pressure) This can be found in the specifications of the material. |

80400 |

80400 |

|

d |

Wire thickness |

In millimeter (mm) |

? |

? |

|

Dm |

Diameter spring center to center |

In millimeter (mm) |

? |

? |

|

Nw |

Working turns |

Number |

? |

? |

How do I get from a spring constant of tension springs to a tension spring design?

The data to be found are:

- Tension springs with a spring rate of 17 N/mm (50 Newton preload)

- Tension springs with a spring rate of 13 N/mm (50 Newton preload)

First, we recommend finding standard extension springs within the parameters. In order to arrive at a custom extension spring design, we continue with the calculation of the wire thickness (d), Center to Center diameter of the spring (Dm) and the number of working windings (Nw). Below are some options for designing the tension spring. The options of the parameters of the tension spring can be calculated infinitely without limitations.

| Example 1 | Option 1 | Option 2 | Option 3 | Option 4 |

| G | 80400 | 80400 | 80400 | 80400 |

| d (mm) | 0.65 | 0.65 | 5.00 | 4.00 |

| Dm (mm) | 2.00 | 3.00 | 30.00 | 30.00 |

| Nw | 14.00 | 4.15 | 14.5 | 5.9 |

| C (N/mm) | 16.02 | 16.01 | 16.04 | 16.15 |

For the second example. With roughly the same parameters.

| Example 2 | Option 1 | Option 2 | Option 3 | Option 4 |

| G | 80400 | 80400 | 80400 | 80400 |

| d (mm) | 0.65 | 0.65 | 4.65 | 4.00 |

| Dm (mm) | 2.20 | 3.00 | 30.00 | 30.00 |

| Nw | 14.00 | 5.50 | 14.50 | 8.00 |

| C (N/mm) | 12.03 | 12.08 | 12.00 | 11.91 |

To reproduce this formula, the following can be used at C:

=(C2*(C3^4))/(8*(C4^3)*C5)

The limitations are:

- The free length in which the spring must move,

- The spring index,

- Goodman chart (lifetime).

Check on the tension spring designs found.

Now that we have found a spring constant for the desired spring, we can continue to calculate to arrive at a design of a spring. We have clearly set the following parameters 8 times: The wire thickness, the center-to-center diameter and the number of turns.

With these parameters, the following parameters can be found:

- Body length

- Length for eyes of tension springs

- Untensioned length of tension spring

The foregoing parameters, together with the spring travel, result in the minimum required free space that the spring requires.

The minimum clearance for the tension springs:

Going back to the beginning, we want this spring to stretch at least 50mm. Contrary to the calculation of free space of compression springs, tension springs of free space are not equal to the unstressed length. The free space is necessary to obtain the forces over a certain spring travel and to place the spring in it.

Calculate the length of the extension spring body (Lk)

The body of the spring is the first parameter needed to calculate the free length. The length of the body (Lk) is the wire thickness times the number of turns. After that there is a safety correction of 1.0064 times the result.

Lk = Wire gauge * Number of turns * 1.0064

The Lk is the spring without fasteners (eyes) in untensioned length. To calculate the full untensioned length, the eyes should be included.

Calculation of eye length on extension springs

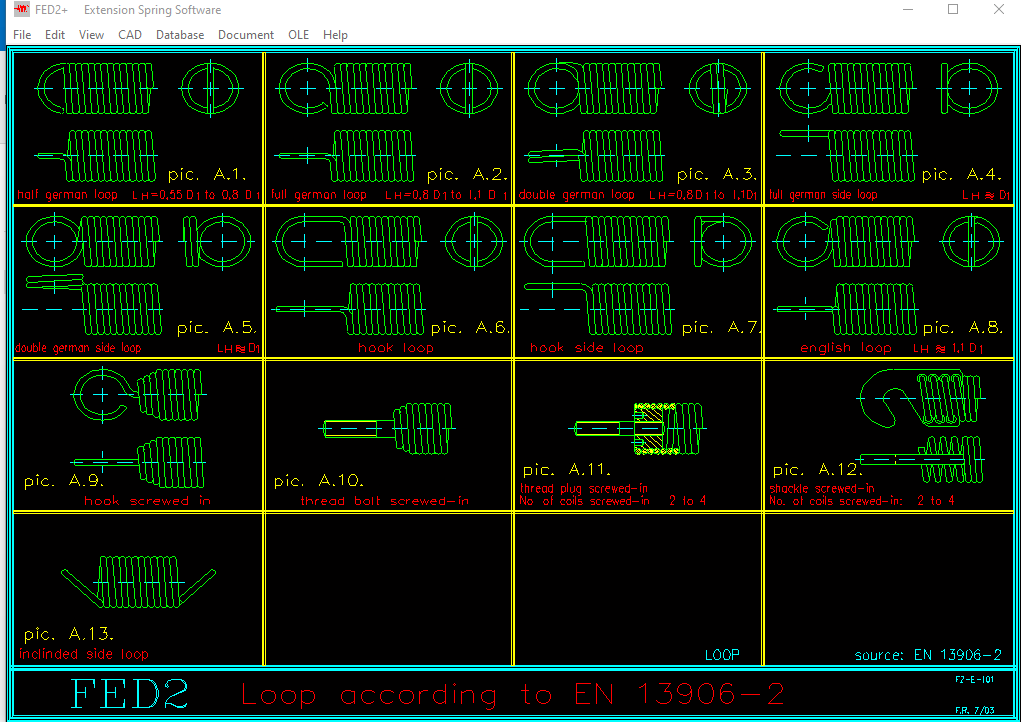

In this example, default German eyes apply. All eyes are shown in our piece of eyes on extension springs. As a short repeat for the most standard eyes; German and English eyes:

Length German eyes = Di x 0.9

Length English eyes = Di x 1.1

To calculate this, the Di (Internal Diameter) is required. Use Dm – d for this. Furthermore, we want two eyes on these tension springs, so we will have to multiply the eyes parameters by two.

Spring untensioned length

To calculate the free space then it is necessary to add the body (Lk) together with twice the length of the eyes (LH).

L0 = Lk + LH

The untensioned length at the tension spring is the length it occupies in rest position. The tension spring only provides force when it is stretched.

The minimum required free length of tension springs

The last parameter is the required free length to be able to use the spring. The minimum required free length is the suspension travel + L0.

Check on design of extension springs examples:

The examples of extension spring design have been further elaborated. Thus, a total of eight designs were made. It is always wise to go with a test object for three springs, one spring that fits perfectly to the application, one spring that is stiffer than the application and one spring that is slacker than the application.

| Example 1 | Option 1 | Option 2 | Option 3 | Option 4 |

| G | 80400 | 80400 | 80400 | 80400 |

| d (mm) | 0.65 | 0.65 | 5.00 | 4.00 |

| Dm (mm) | 2.00 | 3.00 | 30.00 | 30.00 |

| Nw | 14.00 | 4.15 | 14.5 | 5.9 |

| C (N/mm) | 16.02 | 16.01 | 16.04 | 16.15 |

| Spring dimensions | ||||

| Spring travel (mm) | 50.00 | 50.00 | 50.00 | 50.00 |

| Lk (length body) mm | 9.16 | 2.71 | 72.96 | 23.75 |

| LH (length eyes) | 2.43 | 4.23 | 45.00 | 46.80 |

| L0 | 11.59 | 6.94 | 117.96 | 70.55 |

| Minimum required space | 61.59 | 56.94 | 167.96 | 120.55 |

| Bus size (Dm+d*2) | ||||

For the second example

| Example 2 | Option 1 | Option 2 | Option 3 | Option 4 |

| G | 80400 | 80400 | 80400 | 80400 |

| d (mm) | 0.65 | 0.65 | 4.65 | 4.00 |

| Dm (mm) | 2.20 | 3.00 | 30.00 | 30.00 |

| Nw | 14.00 | 5.50 | 14.50 | 8.00 |

| C (N/mm) | 12.03 | 12.08 | 12.00 | 11.91 |

| Spring dimensions | ||||

| Spring travel (mm) | 50.00 | 50.00 | 50.00 | 50.00 |

| Lk (length body) mm | 9.16 | 3.60 | 67.86 | 32.20 |

| LH (length eyes) | 2.79 | 4.23 | 45.63 | 46.80 |

| L0 | 11.95 | 7.83 | 113.49 | 79.00 |

| Minimum required space | 61.95 | 57.83 | 163.49 | 129.00 |

| Bus size (Dm+d*2) | 3.50 | 4.30 | 39.30 | 38.00 |

Order tension springs

You can order the tension springs easily and quickly from Tevema. All standard springs are produced with German eyes in any position. Extension springs are available in different materials. In addition to various materials, Tevema offers a wide range of post-treatments.