We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Blog - Preload on tension springs

Extension springs are the most commonly used technical spring after compression springs. The name of the extension spring is given to the application of extension springs. The springs are pulled out, and then forcefully retracted to the original position. The compression springs compress the spring and then push it back to its original position.

- This is also reflected in the English definition, which is usually displayed as (Ex)tension spring. Extension is withdrawal and pull back, and the tension is the preload wich defines the preload on the spring.

In this piece you will read about preload combined with the topics:

- How do forces on tension springs arise?

- How are tension springs fixed?

- What about forces and eyes on tension springs?

- Order extension springs, what to take into account?

Visuals above: The windings of tension springs are wounded closely together, where with compression springs the windings are set closely from each other.

How does force on tension springs arise?

The tension springs, unlike compression springs, have no space between the turns. The coils of tension springs are wound in such a way that the coils want to crawl on top of each other, this is only impossible due to the design. So each turn provides power to the previous turn. This ensures that the tension spring always provides force to return to the original position. However, this wrapping method has an additional effect. Due to the tight winding method, there is preload on the tension spring. The preload (F0) means that a minimum force is required to get the tension spring moving at all.

As an example the T30620 has an F0 of 0.96 Newton and a spring rate of 3.27 Newton per mm of extension. Before we can pull out the spring one millimeter, we must first place 0.96 Newton on the extension spring. Then we can extend the tension spring one millimeter with 3.27 Newton.

How are tension springs fixed?

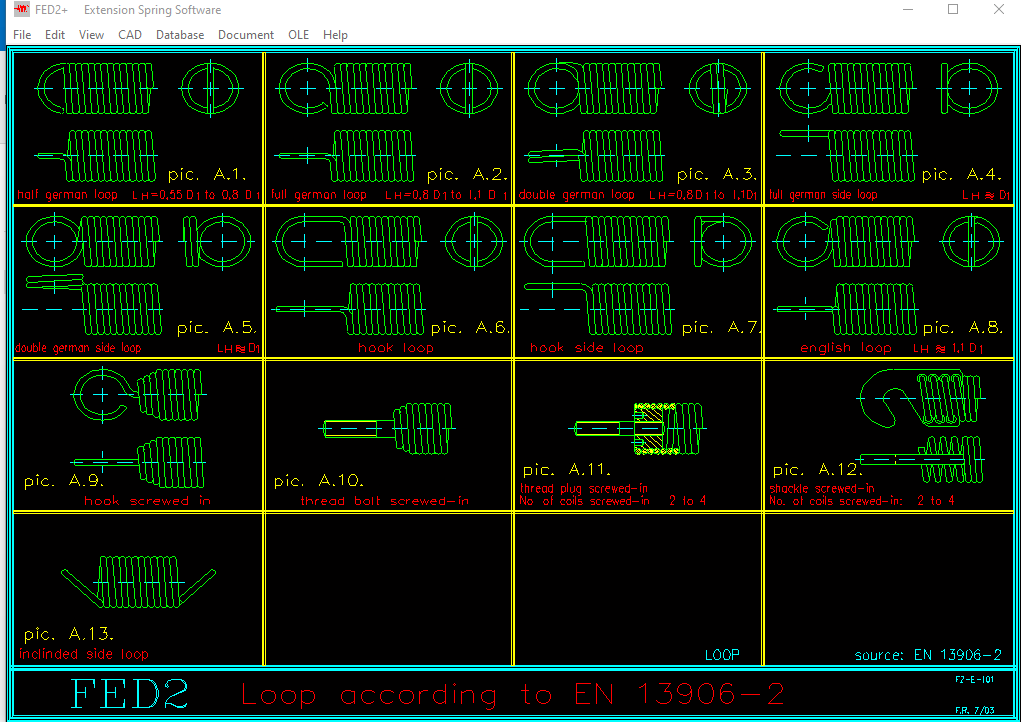

It is standard that the smaller extension springs have eyes. The eyes of tension springs are attachment points to which the tension spring can hook onto a hole. There are a number of standard options for extension springs:

- German eyes (Double, whole, half)

- English eyes

- Hook eyes

- Screwed in eyes

- Bolt/plug/thread

You can find out what this all looks like in our explanation of eyes on tension springs. The eyes of tension springs can be placed on the side or in the middle. With standard springs, the eyes are attached to the direct end of the last coil (turn) of the tension spring. This provides the best form to transfer forces. This is important because eyes of tension springs break off.

Why do eyes on tension springs break off?

The eyes on tension springs break off because of their function of transmitting force. On a compression spring, force is applied directly from a pressure plate (or similar) to the turns, which then press directly on the first coil (turn) of the spring. In the case of the extension spring, the first force falls at the point at which the pretension of the extension spring and the force of the extension movement, so to speak, meet. Eyes on extension springs usually break off here. This can be in millions of pulls out, but in many applications where the springs are given too much force, it is sooner. This can be seen in the Goodman diagram, ask our sales department for specifications of a chart of a relevant tension spring. The breaking of an eye can be prevented by using screwed eyes or a bolt/plug/thread. There is a caveat to this, however, that the force transmitted now comes to a turn of the tension spring.

Order extension springs, what to take into account?

If you order extension springs, always take into account the preload of the extension spring. The following installation dimensions are also important:

- Total extendable length,

- Length difference between body and body + eyes,

- Inner and outer diameter of the spring,

- Materials and applications thereof,

- That extension springs can best be pulled out in a straight line (dynamically possible, but always ask our calculation department for a calculation).

For the choice of eyes, the standard German eyes on tension springs are good to use in most applications. If you have specific requirements for your extension springs, you can request these via our online customized extension springs option. If you would like to request more information about the desired extension spring, please send an email to the sales department that's most close to your location.