We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Filter By

Request an quote for your suspension springs. Available from 50 pcs.

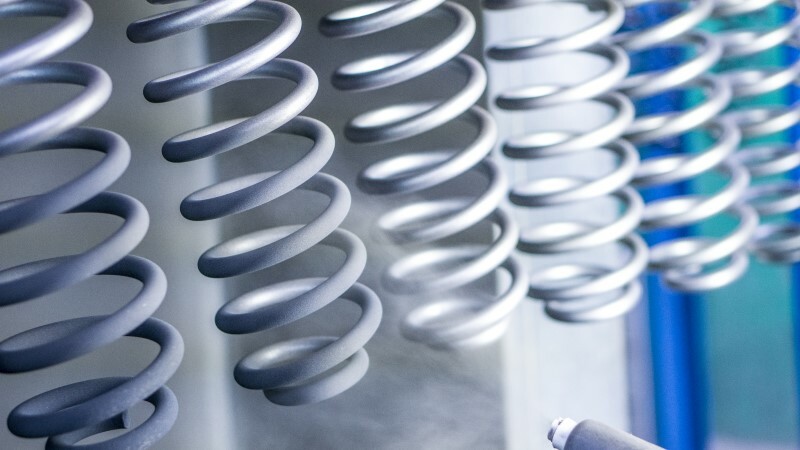

At TEVEMA we manufacture over 9,000 suspension springs for Original Equipment Manufacturers (OEM) and for after-market under your own brand name (or with the TEVEMA name, whichever you prefer). TEVEMA suspension springs are used in more than 20,000 applications.

For our production of suspension springs we use cold spring steel produced with high quality chromium silicon pre-hardened steel. This provides a tensile strength of up to 2,100 MPa (million pressure per square meter, 21 bar per m2)

All TEVEMA technical springs are made with the greatest care. Our concern for quality and reliability is even more acute with suspension springs. At TEVEMA the machines are equipped with advanced control systems. In addition to quality control by machines, the suspension springs are also manually checked per batch. This is how TEVEMA ensures that every suspension spring is perfect.

To ensure the maximum usability of our suspension springs, TEVEMA has initiated a heat treatment after the spring steel wires have been formed as suspension springs. The heat treatment reduces the internal stresses introduced during the elastic deformation process. Heat treatment also increases the strength of the suspension spring (the increase in strength depends on the choice of material). Due to the heat treatment, the technical spring now has a high degree of elastic deformability and guarantees the maximum output of the material's natural properties. But that's not all.

TEVEMA completes the process of making suspension springs by shot blasting, shot blasting is a cold working process.

Shot blasting is used to produce a compressive residual stress layer and modify the mechanical properties of metals. In this process, on the surface of the technical spring, round metal balls are fired with precise force to create a plastic deformation. This, in combination with deburring and ultrasonic cleaning, ensures maximum TEVEMA basic quality.

coatings

To ensure that all suspension springs retain their quality as long as possible, TEVEMA springs undergo a zinc / nickel / tin surface coating. With power coating and collar lacquer, TEVEMA not only ensures a beautiful appearance of the suspension springs, but also maximum protection.

TEVEMA suspension springs have maximum usability and good quality. TEVEMA offers customers a total concept in service; with identification numbers on the suspension springs, 5 year product warranty and packaging with your label. Contact us at info@tevema.com.pl, Tel: (+48) - (0) 74-8667420