We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Blog - Extension springs technical data

Extension springs technical data

Our extension springs have been specified and designed to high precision standards. We refer to DIN 2089-2/EN13906-2. All our standard extension springs have uniform body diameter and are produced with full twist loops the same diameter as the body. They are wound with initial tension; some force is required before the coils are initially separated. As with other stock components, they are capable of wide application for experimental, development, protyping, and maintenance work.

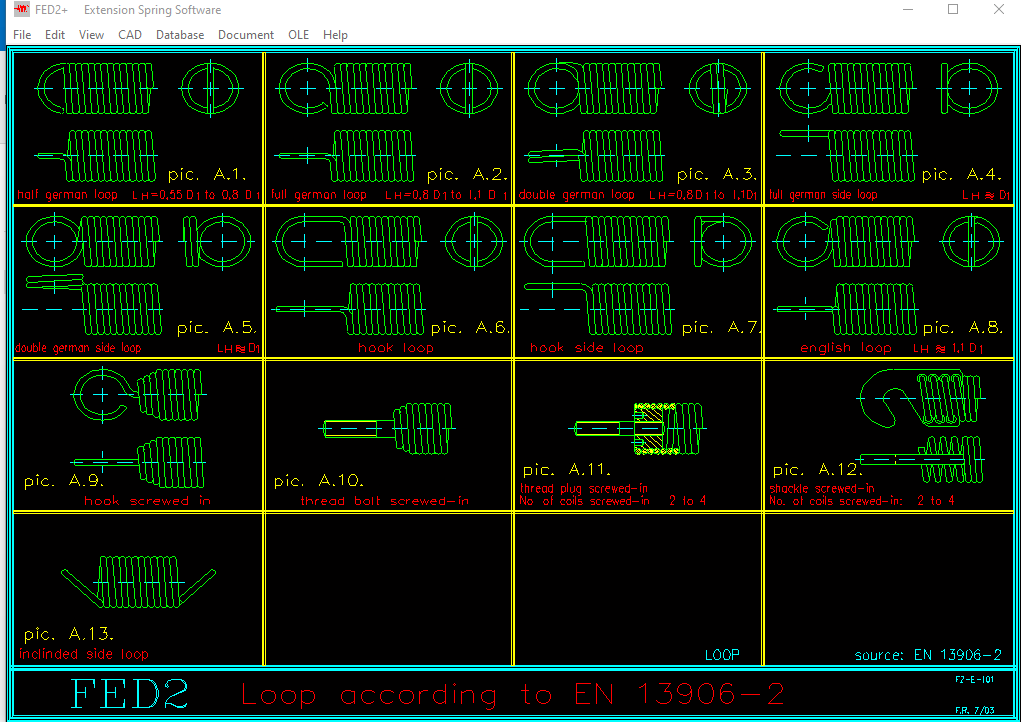

TEVEMA produces extention springs with Full German loops, English loops, hook loops, etc. according to DIN 2097-3.

The standard extention springs are made of:

|

Material: |

|

|

Music Wire: |

Din 17223 C / nr.1.1200 / EN10270-1 |

|

Stainless steel: |

Din 17224 / X10CrNi 18-8 / AISI 302 / nr. 14310 / AISI 302 / EN10270-3 |

|

Tolerances: |

Din 2076-2 / EN10270-2 |

|

Production: |

|

|

Coiled: |

Right hand |

|

Loops: |

2 german loops closed according to DIN 2097-3. In any position.. |

|

Toleranties: |

Din 2097-2

|

Surface treatment:

The springs are oiled. On request it is possible to supply them against an additional price with other surface treatments. However these are not available from stock.

Special Extention Springs

Our production department can make almost every extention spring on measure in as well small as large quantities. The extention springs can be made with different ends, which you can find in DIN 2097 site 3. We can produce them from different materials such as music wire, stainless steel 302 or 3.16, exotic materials like inconel, ninomic, fosfor bronze, beryllium copper (CuBe2), molybdeen, wolfram, titanium etc. Our engineering department can help you to find the right spring. We can also take care for different after treatments like passivating, epoxy coating, chemical blacking, chromium plating, nickel plating, electrolitical polishing, sink plating, silver plating, gold plating, cleanroom packaging etc.

ENDLESS GARTER SPRINGS

Garter springs are extension springs whose ends can be screwed into each other, which results in a ring-shaped springs. They mainly used to maintain a defined pressure in end closures, for compensation of losses at the edge or of volume changes induced by fluids or temperature. Moreover, they may serve as short transmission belts or for electrical connections.

These springs have a high initial tension in order to maintain a maximum of constant force. The ends are coiled in such a way that they form a strong junction although the external diameter remains merely unchanged. Garter springs are available in several lengths, but their length can be adapted by just cutting off the unnecessary portion at the cylindrical end. Afterwards, the endings can still be screwed into each other.

Material:

Stainless steel: RVS 302, DIN 17224

Tolerances: for external diameter +/-0.13; for a tension of 4.75 extension +/-10%

Production;

Coiled: right hand