We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Blog - Helical coil springs, which spring do you need?

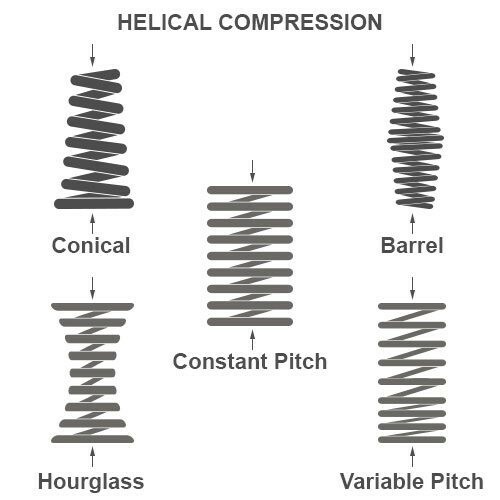

The five types of coil springs

There are five types of helical coil spring. Each type of helical coil spring has a different application. The five types of helical coil springs are: constant pitch helical coil springs, conical coil springs, barrel coil springs, hourglass coil springs and helical coil springs with variable windings. In this piece the five types of helical coil springs are explained. First of all, the definitions of the five types of helical coil spring are given, and afterwards, the differences and applications of the five different types of helical coil spring are described.

1. Standard compression springs

Coil springs are versions of compression springs. The most common type of compression spring is built up by constant windings. For the constant pitch (space between coils) all coils of the compression spring are equally spaced. The constant pitch coil spring is the standard known compression spring.

2. Conical Compression springs

The second type of compression spring is the conical compression spring. Conical compression springs have a pyramid shape. The pyramid shape of the helical coil spring makes it possible to supply forces in a limited space (axial space). This is because all windings are folded together at full compression.

3. Barrel springs

The third type of helical coil spring is the barrel spring, this spring owes its name to its appearance which resembles a barrel. A barrel spring is a type of compression spring that produces linear forces where the upper and lower outer diameter are smaller than the middle outer diameter. This allows the spring to save space.

4. Hourglass springs

The fourth type of compression spring is built like an hourglass, this helical coil spring has a higher upper and lower outer diameter compared to the middle outer diameter. These coil springs have a high stability and just like the conical compression springs they are suitable for smaller spaces.

5. Compression springs with variabel pitch

The last type of coil spring is the compression spring with variable windings or variable pitch. These compression springs are not constructed with an equal distance between the coils, but the coils are made in sets with a certain space between the coils.

What’s the difference between constant and variable pitch coil springs?

A coil spring with a constant pitch has a linear relationship between forces in Newton and compression in millimetres. For example, when a helical coil spring is placed under a force of 2,668 Newton (N) there will be one millimetre of compression on the compression spring. For every 2,668 N above that, the spring will be compressed again by one millimetre regardless of how far the coil spring is already pressed.

A compression spring with a variable pitch has a progressive relationship between forces in Newton and compression in millimetres. As an example we have a helical coil spring with a variable pitch with a spring constant of 1.890 - 2.668 Newton. This means that at the beginning at 1 millimetre of compression the spring is loaded below 1.890 Newton, but the more the compression spring is compressed, the more force is needed to compress the coil spring by one millimetre. This can go up to 2,668 Newton. Simply put, gradually more Newton is needed per millimetre of compression.

What are barrel springs?

A barrel spring is a helical coil spring that delivers linear forces, the upper and lower outer diameters are smaller than the middle outer diameter. A barrel spring prevents kinking and is suitable for smaller spaces. The prevention of kinks applies when a compression spring is four times as long as it is wide.

Barrel springs can be telescopic or non-telescopic. Telescopic barrel springs have the characteristic that the smaller coils go into the larger coils when the coil spring is pressed. With non-telescopic coil springs, the coils are pressed together when the coil spring is compressed. The barrel springs are technically more difficult to design than the standard compression springs, this is due to the forces that these coil springs produce not always being linear. This occurs when the barrel spring starts telescoping. Barrel springs are often used in the toy industry, drinking bottles where water has to be mixed with other substances and the furniture industry. Barrel springs are available from TEVEMA on request, these can be requested via our custom-made compression springs form.

What are hourglass coil springs?

Hourglass-shaped compression springs, also called hollow springs, have a smaller diameter in the middle of the spring and a larger diameter at each end. The hourglass springs have a high wire capacity and can handle high horizontal and conical displacements due to their unique design. The absorption of fluctuations is especially important in the production of cars and consumer goods. But these coil springs are also applicable in the production of trains, freight cars and subways. Hourglass springs are available from TEVEMA on request. You can request these via our custom-made compression springs form.

Order all kinds of helical coil springs at TEVEMA

All helical coil springs are available for sale at TEVEMA, only the standard compression springs and standard conical compression springs can be found on our online shop. It is possible to have compression springs custom made. TEVEMA only make these compression springs to order when the technical specifications are often product related and there are no standard products available.