We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

How to measure a compression spring

You measure compression springs by writing down the following parameters step by step.

You will need a compression spring to follow this guide:

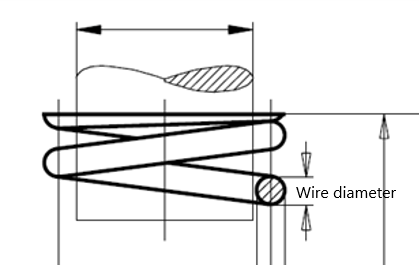

Step 1: Measure the spring wire diameter up to 2 decimals. Take wire diameter in the middle of the compression spring ( not one of the ends )

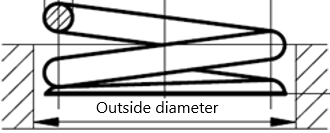

Step 2: Measure the outside diameter of one of the coils in horizontal state. Coils can have a slight variation of outside diameter always take the largest one.

Note, if the outside diameter changes to mutch, please look at conical compression springs, or other kinds of compression springs.

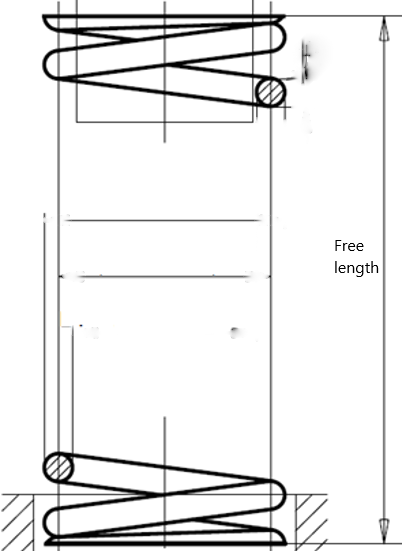

Step 3: Measure the length in its uncompressed condition. (without any force applied)

Step 4: Determine the ends on the compression springs. Compression springs can have the following ends:

- Open

- Open and grinded

- Closed

- Closed and grinded

Read more about the ends on compression springs.

Step 5: Count the number of coils. Also take in account the coils on each end.

|

* |

Counting ends on Compression springs |

|||

|

|

Open |

Open and grinded |

Closed |

Closed and grided |

|

Nt |

Na |

Na + 1 (0,5 + 0,5) |

Na +2 |

Na+2 |

|

Hoogte |

(Na+1) d

(Nt+1) d |

Na d

(Nt+1) d |

(Na+3) d

(Nt+1)d |

(Na+2) d

Nt d |

|

Pitch p |

(FL-d)/ Na |

FL/ Na |

(FL-3*d)/ Na |

(FL-2*d)/ Na |

Step 6: Determine the spring wire material type. Wire types can be determined with an magnet, or by operation (high/low temperature exposure, corrosive materials, ect. ) In absence of that, most common material is music wire.