We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Blog - Detailed information of ISO 11901 Gas springs

Selecting the right nitrogen gas spring can be tricky. In this article you can read about the different ISO 11901 nitrogen gas springs and the advantages of each type of nitrogen gas spring.

Gas springs range

At Tevema we have ISO 11901 gas springs and the “normal” gas springs. The "normal" gas compression and gas extension springs are the gas springs that you find in cars and consumer goods. The gas springs in accordance with ISO11901 are specially made for molds and heavy industrial applications. This piece is about the ISO 11901 gas springs. To read more about the “normal” gas springs, you can follow this link.

ISO 11901 nitrogen gas springs

The nitrogen gas springs are mostly used in die housings and moulds. Nitrogen gas springs in accordance with ISO 11901 are particularly suitable if the installation space is limited and where the forces have to be high. The gas springs are divided into several versions and series. The versions are products built on the idea of gas springs, they include:

- Nitrogen gas ejectors

- Mini gas compression springs

- ISO standard

- Nitrogen gas punches (current only on request)

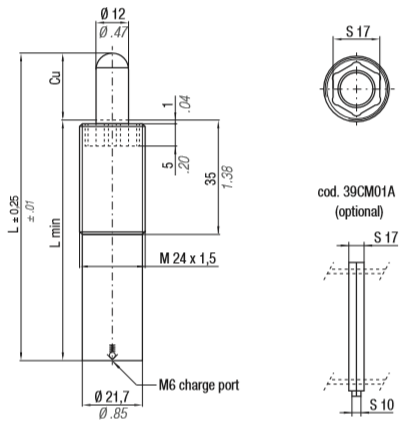

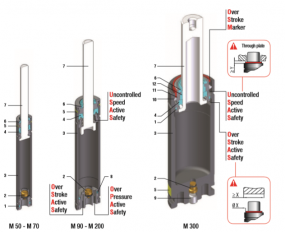

Nitrogen gas ejectors

The nitrogen gas ejectors have a threaded body for maximum flexibility of use, with USAS (Continuous protection against uncontrolled speeds) as standard. The head is rounded, this ensures an improved absorption of radial forces. Like die springs, the nitrogen gas springs have colors (codes) that make the predefined forces recognizable. These color codes can be found in the appendices to the gas spring ejectors. The forces are always adjustable with loading pressures from 10 to 150 bar max. Ideal in the stamping production process and as components of machines and mechanical equipment.

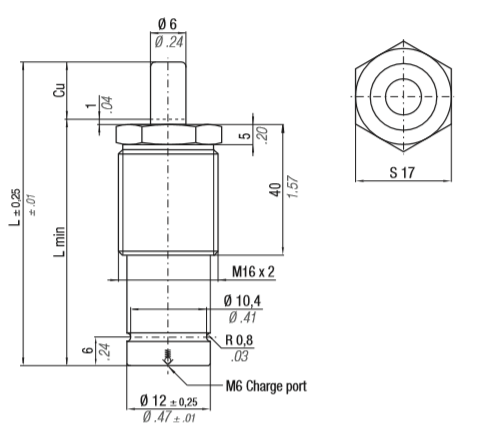

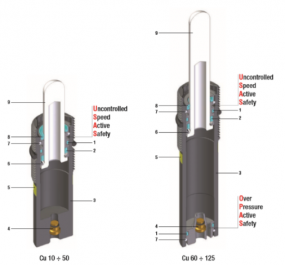

Mini gas springs

Mini gas springs are ideal as a replacement for the standard compression springs. The mini gas springs are available in TBI, TEM, TBM1 and TBM2 threads. Thanks to the different materials in the mini gas spring, you can choose the hardness yourself. In combination with a fast stroke per minute, this mini nitrogen gas springs are one of the most common nitrogen gas springs. These mini gas springs also have loading pressures from 10 to 180 bar. The range of standard forces is defined by the color codes (downloadable from a product page). All nitrogen mini gas springs are always adjustable in strength upon request.

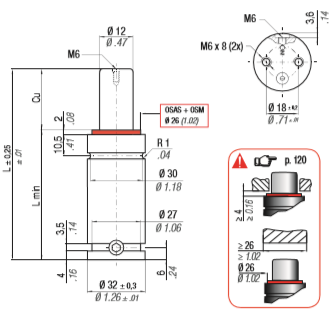

ISO standard nitrogen gas springs

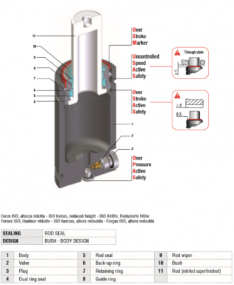

The standard ISO 11901 nitrogen gas springs includes different series. The standard nitrogen gas springs are the SC/SCF series. This series includes a large selection of models and strokes up to 300 mm. All standard nitrogen gas springs are supplied with active flashover protection, active overpressure protection and a protection against uncontrolled speeds. The SC/SCF series have initial forces up to and including 10600 daN. These gas springs are easy to assemble with an easy manifold application (easy manifold is a model where several gas springs are easily linked together and placed in position, contact us for more information).

Based on the SC/SCF series, several series of ISO11901 gas springs have been installed:

- Gas springs with increased strength

- Lowered height gas springs

- Gas springs with reduced height and increased force

- Gas springs with maximum force

- Gas springs resistant to higher temperatures

- Gas springs against vibrations

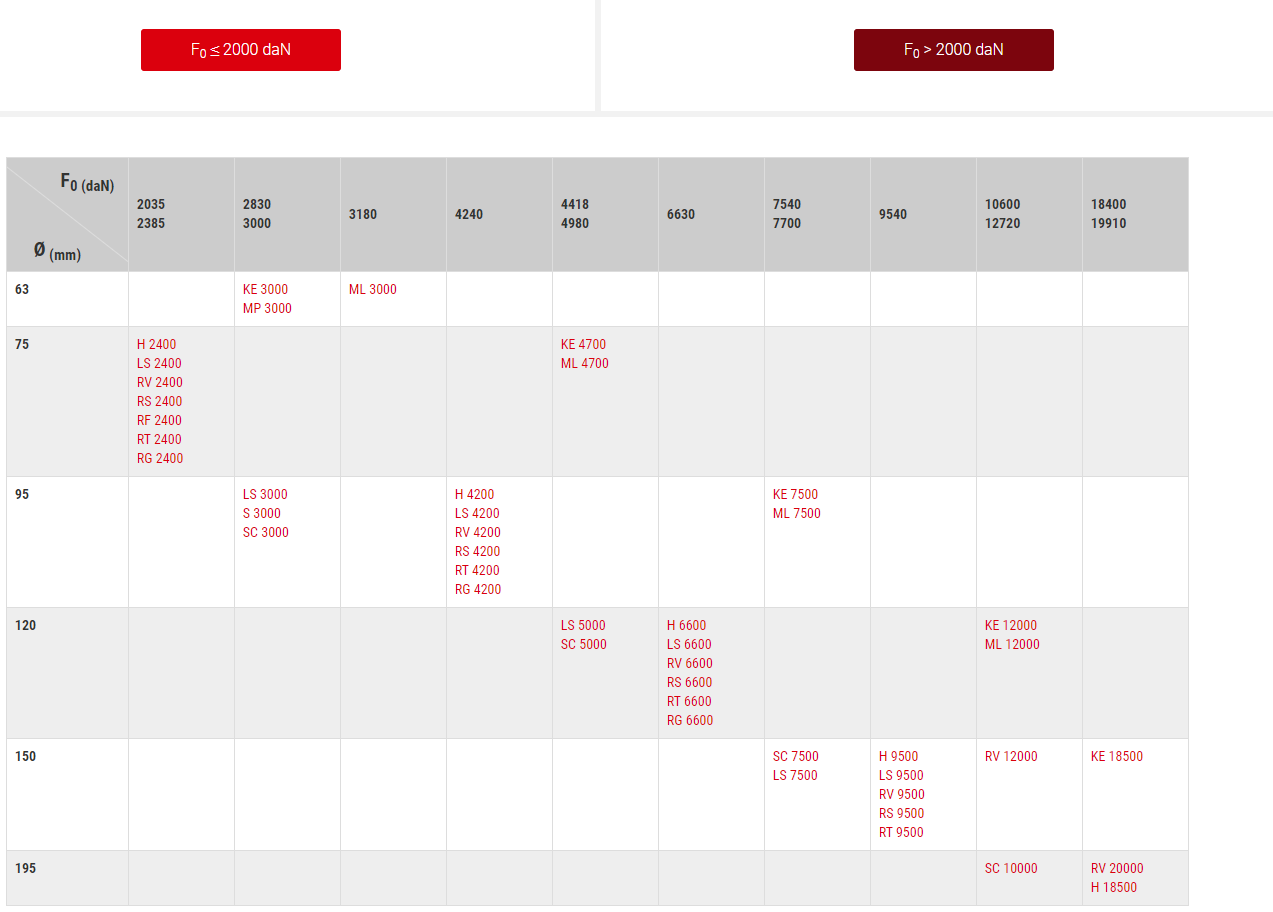

ISO gas springs with reduced height and increased force

The gas springs with increased force are based on VDI3003 and Fiat standard (RF). These gas springs are available from 170 to 19910 daN of initial force. The body range is from 19 mm up to and including 195 mm, with a stroke up to and including 125 mm. These springs are standard with active overflow protection, active overpressure protection and protection against uncontrolled speeds, and they can also be equipped with protection against contaminating elements. The RG variant is suitable for hose cylinders with G1/8 charging port, the RF is adapted to FCA with G1/8 charging port, the RT is adapted to Mazda – Nissan – PSA and Toyota with G1/8 charging port.

ISO gas springs with reduced height

This series has reduced overall dimensions by as much as -50mm compared to the ISO series with equal forces. This compact series is very suitable for space saving. Versions differ in protection.

Gas springs with increased forces

A wide range of models up to a stroke of 300 mm. The initial force goes up to and including 18400 daN. The dimensions are based on ISO, VDI, CNOMO dimensions. These springs are standard with active overflow protection, active overpressure protection and protection against uncontrolled speeds. This series also has extra protection for the ML, MP, MQ and KE series. With protection for the rod.

Gas springs resistant to higher temperatures

These gas springs are specially made to withstand higher temperatures. The gas springs are resistant to either 80-100 degrees Celsius (T1) or 100-120 degrees Celsius (T2). The initial strengths are available from 480 to 940 daN. With a stroke up to and including 300 mm.

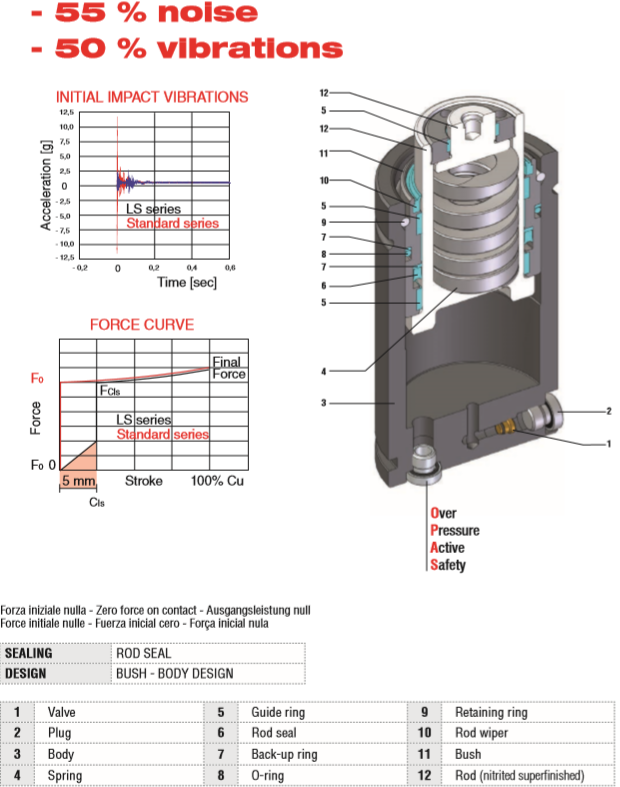

Gas springs against vibrations

These gas springs are equipped with springs on the inside, these springs absorb the first five mm. This ensures that with the gas springs there is a 55% noise reduction and 50% less vibrations. The gas springs are all fitted with active overpressure protection as standard. Available with an initial force from 1590 to 9540 daN.

Order the right gas die spring for your application

You will find all nitrogen gas springs for your application at Tevema. All detailed information can be downloaded online with the respective product. If you would like to receive more information, you can of course always contact the sales department in your area.