We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Blog - gas-springs

What is a gas spring?

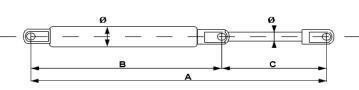

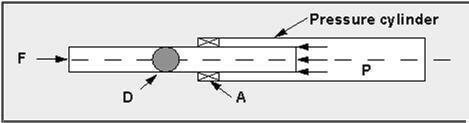

A gas spring consists of a cylinder and a piston rod with a cross sectional area "D".

Seal "A" between the piston rod and the cylinder seals the inside from the atmosphere.

Gaspressure "P" applies pressure to the cross sectional area "D" of the piston rod and gives the theoretical resultant

force "F".

Tolerance

From 200 to 600 N about 7%, above 600 N about 5 %.

Reserve pressure margin

Under extreme conditions (snowfall and/or wind squalls), a reserve pressure margin of + 10 % should

be taken into account when calculating the required force of the gas spring.

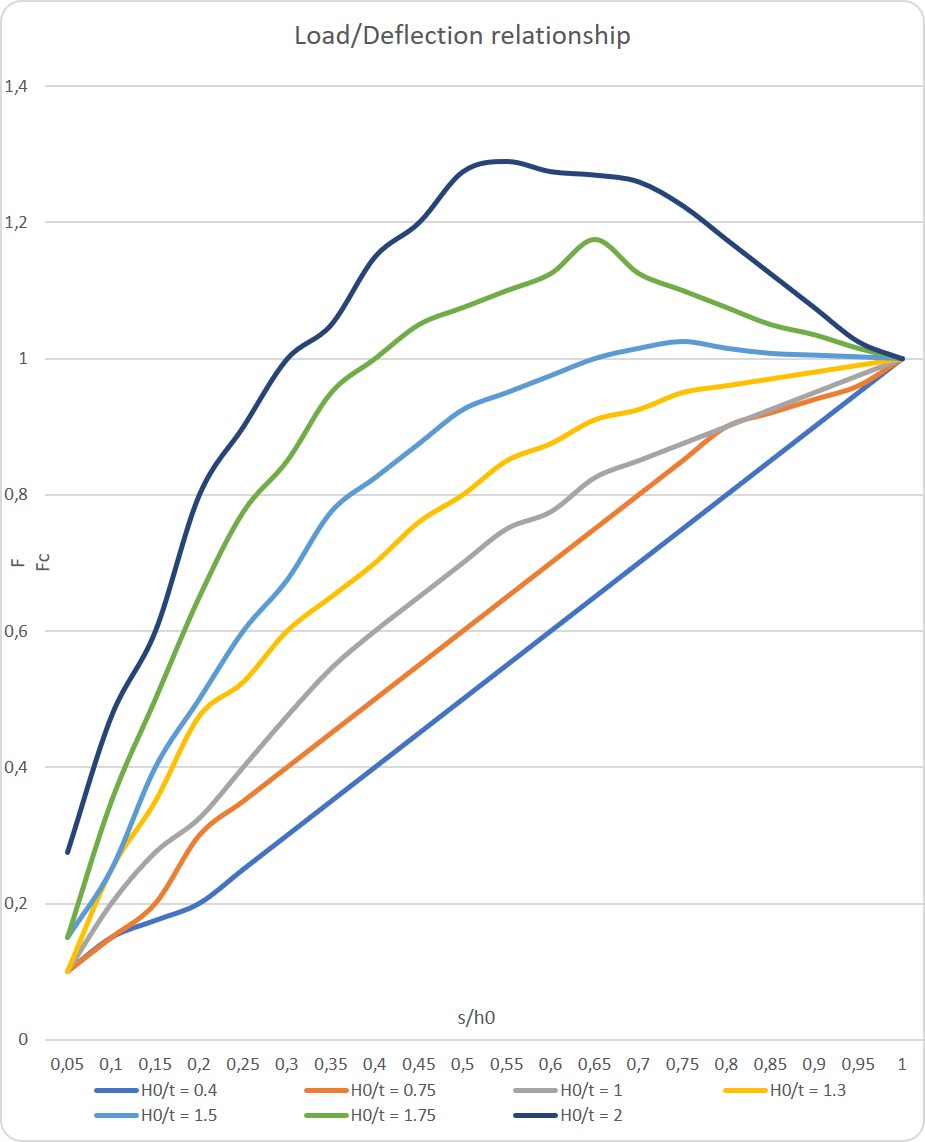

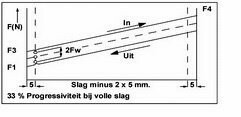

Force linearity

The "progression" of the gas spring depends on the ratio of the volume of the piston rod and the volume of nitrogen.

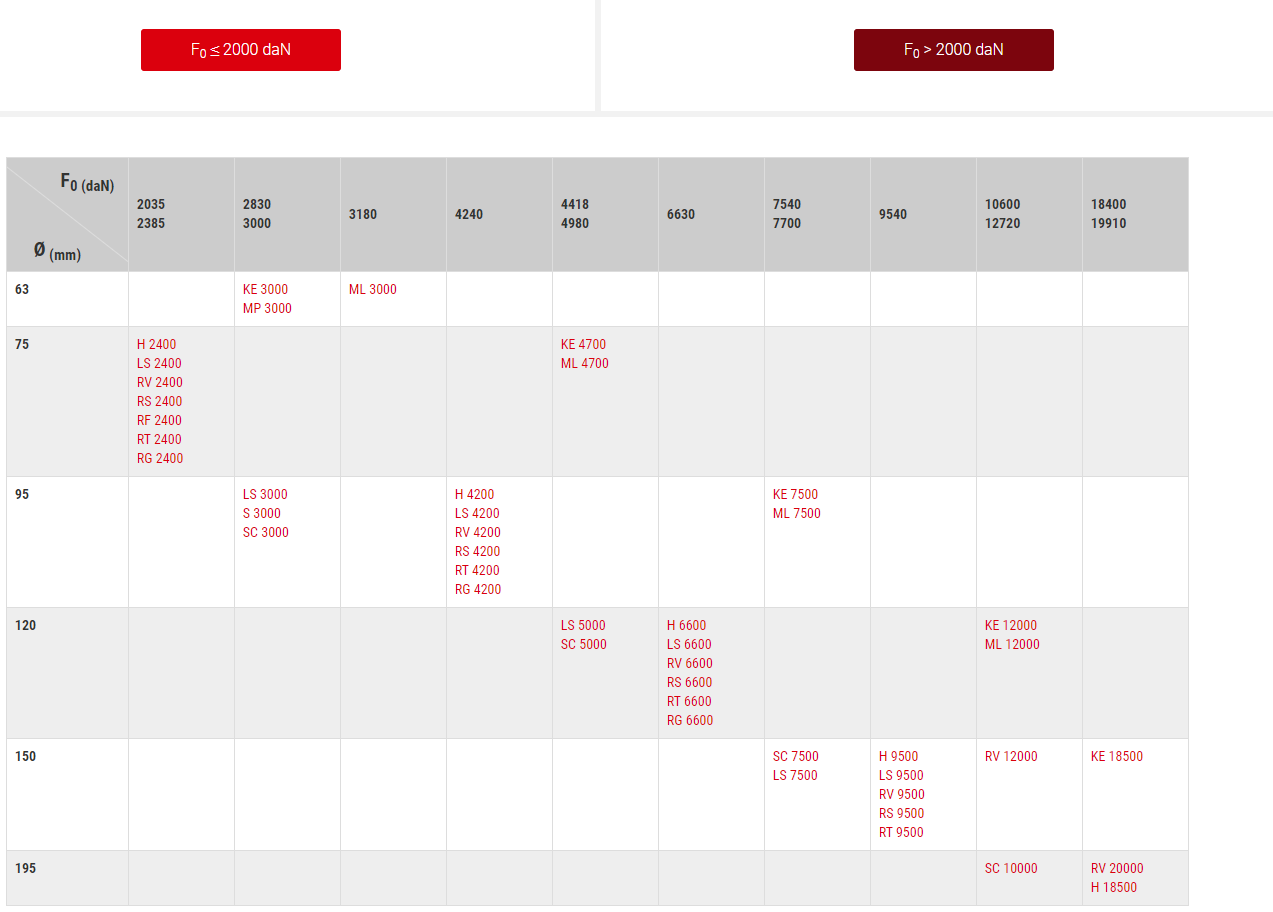

TYPE Full stroke

06-15 27 %

08-19 33 %

08-23 19 %

10-23 33 %

10-28 21 %

14-28 50 %

20-45 33 %

08-28 47 %

By various combinations of extension lengths, piston rod and/or cylinder diameters, an unlimited variation in progression is possible.

The raising of the internal pressure of the gas spring on very fast compression is, due to the related rise in temperature of the gas, at full stroke about 12 % higher.

Installation

Due to the oil cushion present in standard gas springs it is recommended to fit the piston rod at the base.

The oil in the gas spring has a threefold purpose:

1. To lubricate the piston rod.

2. To lubricate the seal.

3. To dampen the end of the stroke.

Durability

Provided the correct installation, maintenance and handling the gas spring has an extensive life.

Attention: Gas springs contain high pressure nitrogen. DO NOT OPEN.

Force

The in- and expulsion force of a gas spring is indicated in N (Newton). 1 Kg = 9,81 N.

Damping of the return stroke

This feature can also be suited to the required application

Stroke - time diagram

Point A shows the extended and point

B the compressed situation. The

difference between A and B = stroke C.

The damping (II) happens both on extension

and compression of the gas spring.

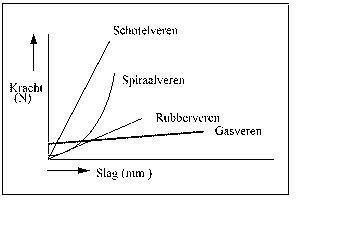

Spring characteristics of several types of springs

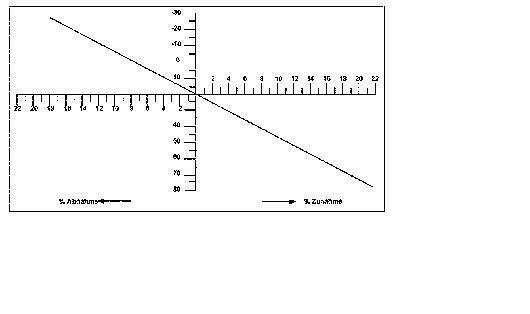

Force variation with temperature

Gassprings can be used in temperatures ranging from -30 to +80oC (normally 20oC). The expulsion force rises/falls according to the difference in temperature

(3,4 % per 10oC variation from the normal temperature).

Selecting a gas spring

The calculation of the correct gas spring is:

G = Weight Valve

Z = startingpoint of the weight

S =schanier point of the valve

D = rotation point of gasspring to valve

O = rotation point of gasspring to fixed frame

A = horizontal distance center of gravity

K = moment arm

X = stroke to rotation point

F = Pull out force

Formular

F = ((GxA) : K) + 10% supplement

Example:

G = 40 Kg A= 500 mm K= 200 mm

Needed Force = (40 x 500) : 200 +10% = 110 kg (= 1100 N)

Guiding principles

Ensure that the stroke of the gas spring is at least as large as the distance (X). By varying the perpendicular distance (K), it is usually possible to select a standard gas spring.

If the gas spring is to be fitted to the flap which is already mounted, and the weight is not known, place a stick or a pole under the far end of this flap with a set of bathroom scales inderneath the pole.

The weight given minus the weight of the stick or the pole should be multiplied by two. The value found will be the weight of the flap.

If the flap is a single piece construction, the distance (A) in the horizontal position is comparable with half the height of the flap.

If rafters or advertising boards hang on the far end, the distance (A) must be calculated, taking this into account. If you find difficulty in finding the right gas spring, we will be happy to advise you.

Special gas springs

Special measurements

We have the facilities available for large-scale production of our standard range. We are also able to produce special variations for specific requirements not met by our standard range.

• Extrem short or long stroke

• Thin piston rod and thick cylinder (progression)

• AISI 316 piston rod

• Aluminium cylinder

• Adjustable gas springs

• Stainless steel gas springs