We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Blog - Tolerances on disc springs

Tolerances of disc springs depend on the respective group of disc springs. A brief summary of disc spring groups is:

- Group 1: Tickness <1.25 mm

- Group 2: Tickness 1.25 t/m 6 mm

- Group 3: Tickness >6 mm

Read more about the complete composition of groups and series of DIN 2093 disc springs. The load / deflection relationship depends on the respective series of the disc spring.

Tolerances on groups of disc springs are important in precision applications. The disc springs can be ordered in several types of metal under various standards.

Tolerances steel thickness, forces and height of disc springs

The tolerances on the disc springs are shown in table below. The thickness of the steel is always the determining factor for the tolerance.

Disc springs in accordance with DIN 2093 have the following thickness tolerances in mm:

| Group | Thickness in mm: | Tollerance in mm: |

| Group 1 | 0.2 up to 0.6 | +0.02 / -0.06 |

| > 0.6 up to < 1.25 | + 0.03 / -0.09 | |

| Group 2 | 1.25 up to 3.8 | + 0.04 / - 0.12 |

| > 3.8 up to 6.0 | + 0.05 / - 0.15 | |

| Group 3 | > 6.0 up to 16.0 | +0.10 / - 0.10 |

Disc springs in accordance with DIN 2093 have the following tolerances on the force in %:

| Group | Thickness in mm: | Tollerance in %: |

| Group 1 | < 1.25 | +25% / -7.5% |

| Group 2 | 1.25 up to 3.0 | + 15% / -7.5% |

| > 3.0 up to 6.0 | + 10% / - 5% | |

| Group 3 | > 6.0 up to 16.0 | +5% / - 5% |

Disc springs in accordance with DIN 2093 have the following height tolerances in mm:

| Group | Thickness in mm: | Tollerance in mm: |

| Group 1 | < 1.25 | +0.1 / -0.05 |

| Group 2 | 1.25 up to 3.0 | + 0.15 / -0.08 |

| > 3.0 up to 6.0 | + 0.2 / - 0.1 | |

| Group 3 | > 6.0 up to 16.0 | +0.3 / - 0.3 |

Order disc springs

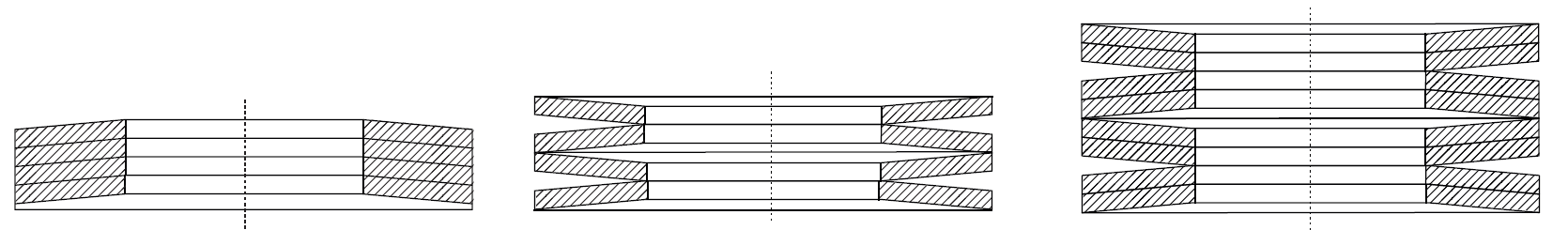

The disc springs according to the DIN 2093 method have alloy steel with the following hardness group 1 HV 425-510 (HRC 42-50) and group 2HRC 42-52 (HV 412-544). Disc springs in group 3 are custom-made. You can easily order disc springs from group 1 and group 2 from stock. All disc springs are standard post-treated with zinc phosphate and oil to guarantee proper functioning. The disc springs are versatile in their applications because you can place stacks of disc springs to deliver precision forces.