We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Blog - Technical data torsion springs

Technical data torsion springs

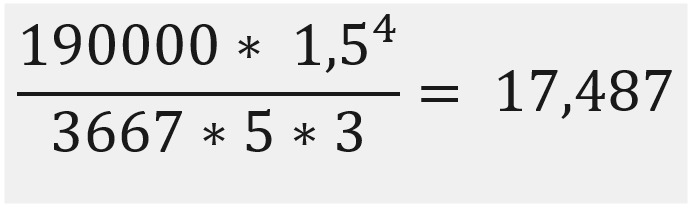

Cilindrically coiled torsion springs are used for creating an axial force or an angular torsion. During tension, the material is exposed to a torsion. Under normal conditions, torsion springs are used over a supporting mandrel or arbour. Application has to be performed in such a way that there is always a tolerance between the internal diameter of the spring and the rode. It has to be taken in consideration that a spring's diameter becomes smaller in case of adjustment of the arms.The load must be applied in such a way, that torsion results in a fixation if the tension increases in that particular direction. In order to reduce friction on the rode, we recommend to use a constant tension at the ends of the legs. Our torsion springs are made according to DIN 2088/ EN13906-3. Tolerances according to DIN2194.

Torsion springs show a lineair spring coefficient. E.g. , if a spring shows a moment of 1 N/mm upon a torsion of 10 degrees, a moment of 2 N/mm will be achieved at a torsion of 20 degrees.

The moment is equal to the product of force times arm length, i.e. M = F X A. The closer to a force acts the end of a leg, the less counter-force will be achieved. If the maximum torsion (alpha) is used, a maximum of 10 000 torsions is allowed. If 80% of the maximum torsion is used, the lifespan is raised to 200.000 to 400.000 loads. If only 70% of the maximum torsion is used, an unlimited lifespan can be expected. Torsion springs are available in left-hand and right-hand coilings. The coiling direction has to be mentioned in your order. Just put a R for right and a L for left after the article code.

The Torsion springs are available in left-hand and right-hand coilings. The coiling direction has to be mentioned in your order. Just put a R for right and a L for left after the article code. The arms in this programme are straight. We can produce any shape of arms. This, however, will result in a surcharge and we kindly ask you to add a drawing or a model. Also you may order springs made of a different kind of material.

Material:

music wire: DIN 17223C / nr. 1.1200 / EN10270-1

stainless steel: DIN 17224/ X12CrNi17.7 nr. 1.4310/ AISI 302/ EN10270-3

tolerances: DIN 2076-2 /EN10270-2

Production:

coiled: right of left ( put a R for right at the end of article number, and a L for Left)

position of arms: The springs are made without deflexions, therefore 180 degrees. On request we can make some extra deflexions. Please look also to our programm of torsionsprings of stainless steel.

|

|

|

|

Surface treatment: The springs are olied. On request it is possible to supply them with other surface treatments, against a higher price.

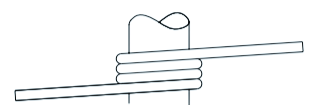

Standard torsion springs made from stainless steel with arms in different positions

These torsionsprings are made of stainless steel according to DIN 17224 /X12CrNi17.7 nr, 1.4310 and are having arms in different positions according to figure. TThe coiling direction has to be mentioned in your order. Just put a R for right and a L for left after the article code. We can also supply the springs in different material against a higher price.

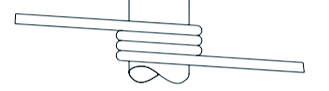

Double-coiled torsionsprings made of stainless steel

In our program the legs of these double coiled torsionsprings are straight. However, we can make them according to your wishes. Herefor we need a drawing or model. The springs can be ordered in other materials and surface treatments.

Special torsionsprings

Our production department is able to make almost every torsion spring on mesure as well in small as large quantities. We are using different kinds of material: Besides music wire and stainless steel, we can make springs of inconel, titanium, wolfram, ninomic, fosforbronze, etc.

Our engineering department can help you to find the right material for your application and to find the right spring. Besides this we can take care of several after treatments like passivating, nickel plating, chemical blacking, epoxy coating, chromium plating, electolitical polishing, sink plating, cleanroom packaging etc.