We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Blog - Technical data die springs

Order DIE SPRINGS

✓ ISO 10243 Die springs

✓ ST Die springs

✓ JIS 5012 B Die springs

In our stock: American Die springs (oval wire), ISO Die springs (rectangular wire) and Die springs made from round wire.

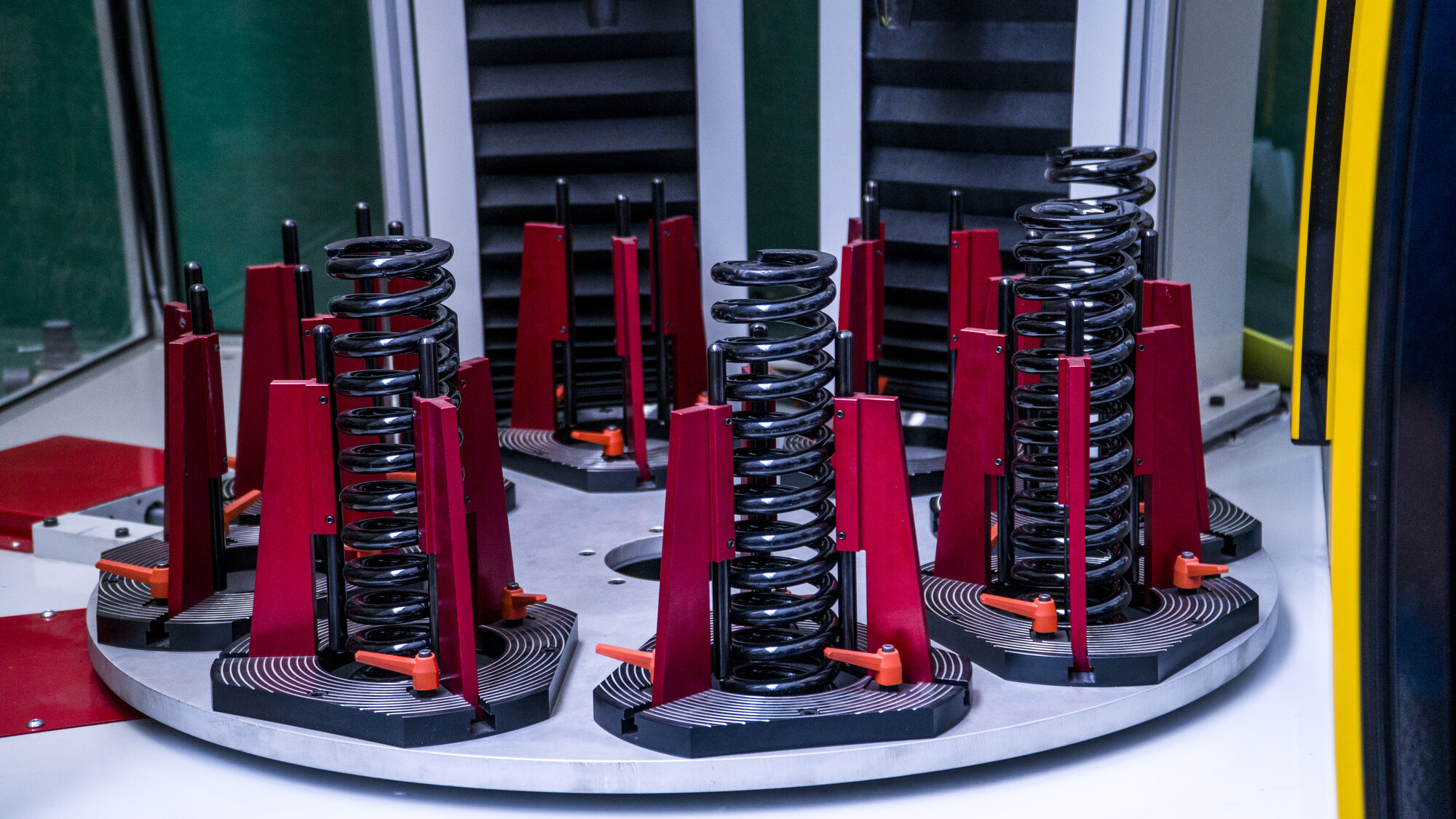

Die springs are developed to create high forces in small areas, as in Die sets. Because of the high frequencies and forces in the die sets, the demands on the die springs are very high. Choosing the right die spring can be confusing. There are different sets of die springs to choose from, which all have their unique colouring codes and definition of light, medium and heavy duty. For every type of die spring we recommend the ISO die springs, because of their low costs and high operating time and low margin of error on free length.

Read more about all types of die springs below. Or go directly to information about:

- Technical information American die springs

- Technical information ISO die springs

- Technical information Round wire die springs

- Technical information JIS die springs

Technical information American Die Springs

American duty springs are made of very high quality chromium vanadium steel (50CrV4/DIN17225/SAE 6150). Because of her oval wire profile a maximum of force and a maximum of lifecycle can be achieved.

American Die springs are marked by r codes as follows:

|

Light duty |

Blue |

|

Medium duty |

Red |

|

Heavy duty |

yellow/copper |

|

Extra heavy duty |

Green |

To count the force at a certain loaded length, you have to multiply the compression lenght with the force rate of the spring.

Working temperature: max. 200 ° C.

In case of higher frequencies, than 1000 strokes per hour, the following values are allowed on the spring stroke (Sn) as a percentage of the free length of the die springs:

- blue springs: 25-30% of free length

- red springs: 20-25% of free length

- yellow springs: 15-20% of free length

- green springs: 15% of free length

The tolerances at loaded length are as follows:

- 0 - 60 mm 2,5 mm

- 61 - 105 mm 3,5 mm

- 106 - 200 mm 5,0 mm

- 201 - 250 mm 6,5 mm

- 251 - 305 mm 10 mm

Technical data ISO 10243 Die springs

The ISO die springs are made according ISO 10243. They are made of Chromium Vanadium steel of a high tensile strength. The ends are squared and grounded. Other coatings are on request deliverable. For more information please contact our engineering department.

The ISO die springs can be used up till an working temperature of 230 grades Celsius.

The colour codes of ISO die springs are as follows:

|

Ultra Light duty |

Light green |

|

Light duty |

Green |

|

Medium duty |

Blue |

|

Heavy duty |

Red |

|

Extra heavy duty |

Yellow |

|

Ultra heavy duty |

Silver |

|

Hyper heavy duty |

White |

In the tabel you will find the values of the max. Spring stroke with the allowed force at a static charge. At a dynamic charge the below mentioned percentages has to be used to find the max. allowed. spring stroke.

|

|

Dynamic 3 milj. cycli |

Dynamic 1.5 milj.cycli |

Static |

|

Light green |

30% of Lo |

40% of Lo |

45% of Lo |

|

Green |

25% of Lo |

30% of Lo |

35% of Lo |

|

Blue |

25% of Lo |

30% of Lo |

33,75% of Lo |

|

Red |

20% of Lo |

25% of Lo |

27,50% of Lo |

|

Yellow |

17% of Lo |

20% of Lo |

22,50% of Lo |

|

Silver |

10% of Lo |

12% of Lo |

13,50% of Lo |

|

White |

5% of Lo |

6,5% of Lo |

7,50% of Lo |

The ISO die springs have an higher accuracy requirements compared to the American Die springs. The ISO 10243 die springs have an maximum operating temperature of 230 Celsius. TEVEMA always recommends the use of ISO die springs compared to the American die springs.

The ISO die springs are made with an special E-coating that ensures 100% coating of the springs. With an minimum thickness of 10 <30 μm coating, the ISO die springs are ensured to have an high corrosion resistance and mechanical strength.

Technical information Die springs with round wire

These Die spings are made of round wire. They are deliverable in 3 versions, light, medium duty and heavy duty with diameters Φ10, Φ12.5 and Φ16 mm.

|

|

Dynamic 3 milj. cycli |

Dynamic1.5 milj.cycli |

Static |

Version |

|

Green |

25 % of Lo |

30% of Lo |

35% of Lo |

light duty |

|

Blue |

25 % of Lo |

30% of Lo |

33,75% of Lo |

medium duty |

|

Red |

20 % of Lo |

25% of Lo |

27,5% of Lo |

heavy duty |

To determine the total compressive force at a certain compression in mm, multiply the compression by the spring constant in N / mm. Then you look at the tolerance on this spring, then you have the rich district in which the punch spring operates.

Technical information JIS Die springs

|

|

Dynamische 1 milj. cycli |

Uitvoering |

|

Yelow |

40% |

Ultra light duty |

|

Blue |

32 % |

light duty |

|

Red |

25,6 % |

Medium duty |

|

Green |

19,2% |

Heavy duty |

|

Brown |

16% |

Extra heavy duty |

|

Gold |

50% (only for 0,5 milj cycli) |

Hyper heavy uty |

JIS die springs are only available on request. Because of their low overall demand in Europe, these die springs must be ordered in quantity. The JIS die springs are perfectly produced. This is why there can't be any deviations in their parameters. If your application needs an precision spring with exactly the an force needed and no room for deviations, the JIS die springs are the perfect solution.

Good to know:

The given limit for load (Fn) or stroke (sn) must not be exceeded, as this will shorten the service life considerably. Outrigger springs must be installed in a pretensioned condition to avoid shock loads. The longest service life is achieved with load and stroke at max. 25%. By default, the winding direction of die springs is right. The die springs are always applied and grounded.

Surface treatments for Stamping springs:

Surface treatments for ISO die springs are possible. For cleanroom die springs the springs are "Unpainted", which means that the colour lining has not been deposited. The unpainted die springs are also suitable for many other post-treatments.